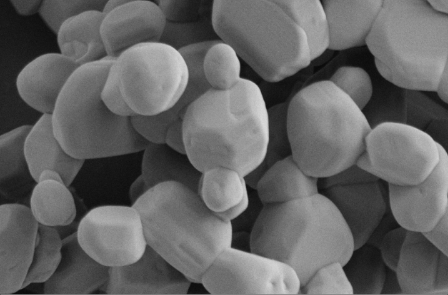

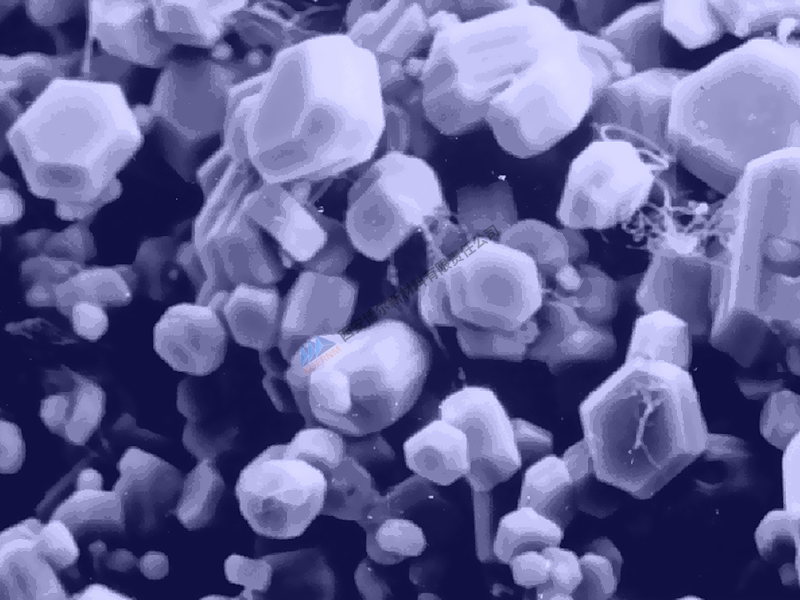

High-purity ultra-fine cubic SiC powder for semiconductor manufacturing

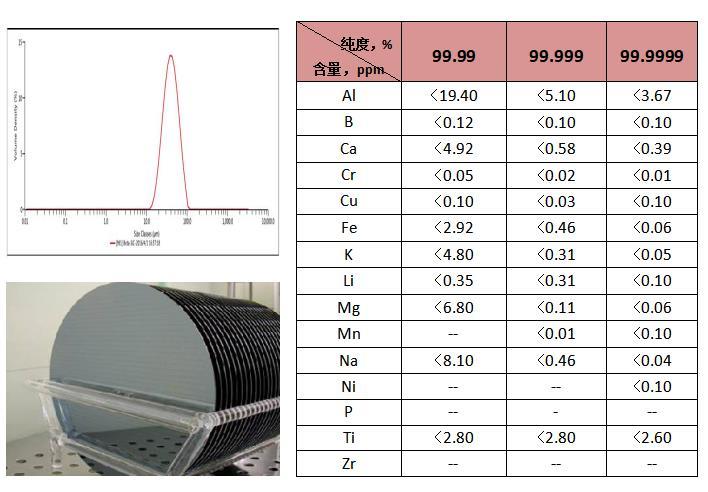

The parent source is micro powder with high purity (99.99%〜99.9999%) and super fineness (0〜0.1μm)

Classification:

High end cubic SiC chip substrate

Key words:

resistant

silicone

Hotline:

High-purity ultra-fine cubic SiC powder for semiconductor manufacturing

Graphic Details

The parent source is micro powder with high purity (99.99%〜99.9999%) and super fineness (0〜0.1μm), and single crystal with particle size (50〜800μm). It can be used to manufacture single crystal silicon carbide using the vapor deposition method. It has excellent electric conduction, heat conduction, wear resistant, heat resistant and corrosion resistant properties, so it can be used as a substitute for electronic-grade monocrystalline silicone and polycrystalline silicone in frontier fields such as military industry, aerospace, and electronics. It is an accepted third generation semiconductor material and LED-used electronic packaging and baseplate material in the high-tech area.

Related Products

Nano SiC thermal conductivity absorbing wave powder

Nano SiC thermal conductivity absorbing powder is made

3C-SiC thermal conductivity absorbing powder

3C-SiC thermal conductivity absorbing powder has the characteristics

The product has high purity, high natural bulk density, narrow particle size distribution

ONLINE MESSAGE

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.