The secret of BYD's electric car battery life with high energy consumption and low energy consumption

IGBT (InsulatedGateBipolarTransistor) stands for "Insulated Gate Bipolar Transistor"

Release time:

2019-03-16

Source:

The secret of BYD's electric car battery life with high energy consumption and low energy consumption

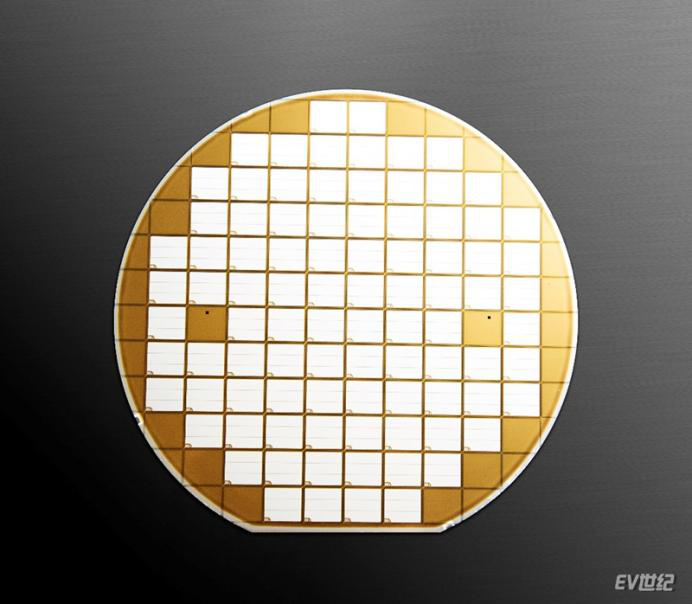

BYD IGBT4.0 wafer

IGBT (InsulatedGateBipolarTransistor) stands for "Insulated Gate Bipolar Transistor". Its chip and power battery cells are also called "dual-core" for electric vehicles. It is a key technology that affects the performance of electric vehicles. Its cost accounts for 5% of the entire vehicle cost. about. For electric vehicles, the IGBT directly controls the conversion of the drive system's direct and alternating current, which determines the vehicle's torque and maximum output power. Thanks to its strong capabilities in core technology areas such as IGBT, BYD's ultra-high battery life and low energy consumption were realized.

As China's first car company to achieve mass production of automotive-grade IGBTs and the only car company with a complete IGBT industrial chain, BYD also released another blockbuster news: BYD has invested heavily in the layout of performance More excellent third-generation semiconductor material SiC (silicon carbide) is expected to launch electric vehicles equipped with SiC electronic control in 2019. By 2023, BYD's electric vehicles will be fully equipped with SiC electronic control.

Although IGBTs will still be in short supply for a long time to come. However, BYD has also foreseen that with the continuous improvement of electric vehicle performance, higher requirements are imposed on power semiconductor components, and the current IGBT will also approach the performance limit of silicon materials. The search for new semiconductor materials with lower chip losses, stronger current output capabilities, and higher temperature resistance has become a general consensus among the academic community and the industry.

It is reported that BYD has invested heavily in the layout of the third-generation semiconductor material SiC, and will integrate the entire industrial chain of SiC-based semiconductors such as materials (high-purity silicon carbide powder), single crystal, epitaxy, chips, and packaging, and is committed to reducing the manufacturing of SiC devices. Cost to accelerate its application in the field of electric vehicles.

At present, the only electric vehicle on the market that uses SiC silicon carbide power semiconductor components is Tesla's Model 3, which uses 650V SiCmosfet from STMicroelectronics. Compared with the traditional IGBT on ModelS / X, SiCmosfet can bring efficiency improvement of 5-8%, which plays a significant role in improving the endurance and reducing energy consumption performance. In addition, SiCmosfet also has a huge advantage in high-temperature performance, which can maintain a normal efficiency performance within 200 ℃, which provides the possibility for the development of high-performance electric vehicles.

After ST France, Infineon Germany has also started the supply of SiC power semiconductors, and its partners are also Tesla. In other words, almost all SiC power semiconductors on the global market have been purchased by Tesla. If BYD successfully launches car-grade SiC power semiconductors in 2019 and applies them to its high-performance models, BYD will undoubtedly establish its position as a brother in the domestic new energy market, and it will truly be in terms of performance and endurance. It is close to Tesla and it has opened a gap with other domestic companies.

In 2018, the company's product "cubic silicon carbide fine powder" was reviewed by an expert group organized by the Provincial Ministry of Industry and Information Technology in conjunction with the Provincial Department of Finance, and was identified as "the first batch of domestic key new material application products." This is undoubtedly the product, the company Fully sure! After 30 years of research and development, the company's research and development team has been consistent and strives for excellence, and has only today's glory. At the end of 2017, the company passed the identification of "Xi'an High-tech Enterprise" and "National High-Tech Enterprise" respectively. In 2018, the company's chairman and team leader, Professor Wang Xiaogang, was awarded the "Xi'an Entrepreneur Hero" and "Xi'an Top Ten Entrepreneur Outstanding" People ". The produced cubic silicon carbide fine powder has high purity, narrow particle size distribution, large bulk density, high sintering activity, and regular crystal structure. The company has pioneered the mass production of nanometer silicon carbide.

company,carbide

Previous Page