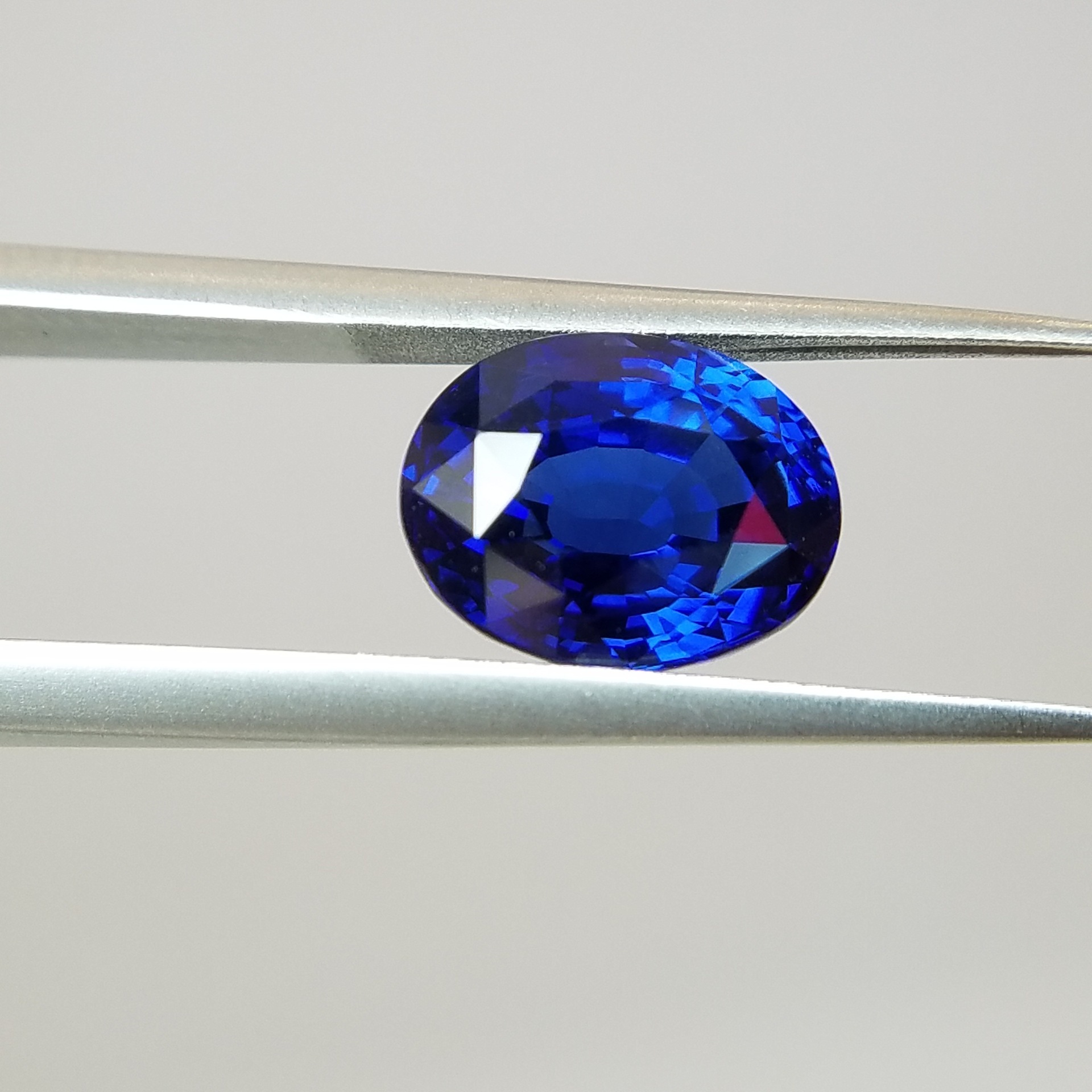

Application of polishing liquid: sapphire wafer

Sapphire (a-Al2O3) is a multifunctional oxide crystal that combines excellent optical

Release time:

2019-01-25

Source:

Sapphire (a-Al2O3) is a multifunctional oxide crystal that combines excellent optical, physical and chemical properties.

As a sapphire substrate for the growth of GaN by metal organic chemical vapor deposition (MOCVD), the surface is required to be ultra-smooth and damage-free. At present, a super smooth surface refers to a surface having a surface roughness of less than 1 nm (RMS). Non-damaged surface means that the processing surface must not have a processing metamorphic layer, and the surface lattice is complete.

Since sapphire has high hardness (Mohs 9.0) and great brittleness, its machining is very difficult, and the preparation technology of non-damaged super smooth surface is more complicated. The polishing liquid is widely used in its processing process. Different polishing liquids have different grinding effects on sapphire, and the polishing liquid has a good response to the improvement of sapphire crystal grinding efficiency and surface quality.

Using a polishing liquid with good self-sharpness, fast grinding speed, and high processing accuracy is the most suitable for sapphire wafer damage-free ultra-smooth surface grinding and polishing.

Grinding liquid and polishing liquid prepared by using our company's proprietary patented cubic silicon carbide powder (Mohs 9.5 ~ 9.75) as raw materials. It has the advantages of good self-sharpness, fast grinding speed, high processing accuracy, and good surface quality. . It is suitable for grinding and polishing of stainless steel, copper, aluminum, cast iron, sapphire wafer, glass, ceramics and other materials. The effect is comparable to diamond, the price is less than one tenth of diamond, and it has a high cost performance.

Note: The equiaxed structure of cubic SiC crystals has better natural sphericity than α-SiC, B4C, BN, BIN, diamond and other materials, and has better grinding and polishing effects in precision polishing.

Grinding fluid and polishing fluid produced by the company

The preparation process of the company's polishing liquid and polishing liquid has been granted two invention patents authorized by the State Patent Office: "A method for preparing a nano-polishing liquid", patent number: ZL201610703064.7 and "a suspension of aqueous polishing liquid. Preparation method ", patent number: ZL201610648321.1.

Strict particle size control, particle size distribution index is better than industry and national standards.

After the purification process, the impurity content can be reduced to the order of one hundred thousandth.

We can customize the configuration of particle size and concentration according to the specific requirements of users. This product has now achieved mass production and has won unanimous approval from users.

Excerpt from: "Sapphire wafer nano-level ultra-smooth surface processing technology"

concentration,thousandth